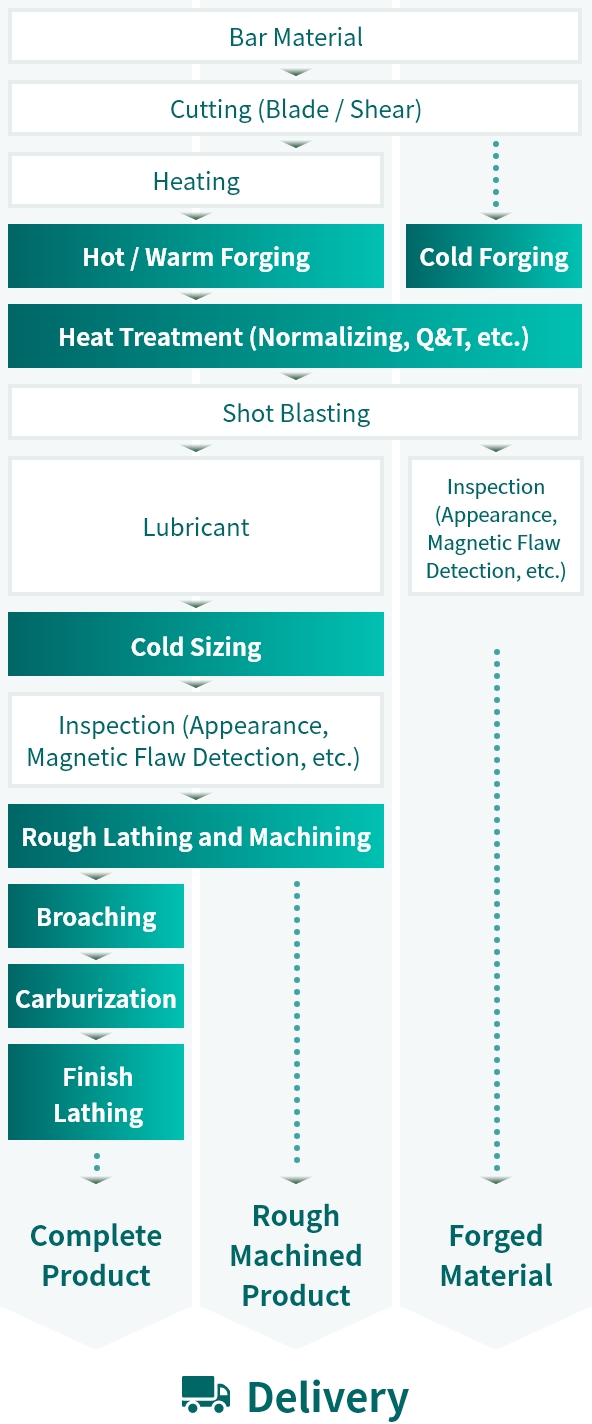

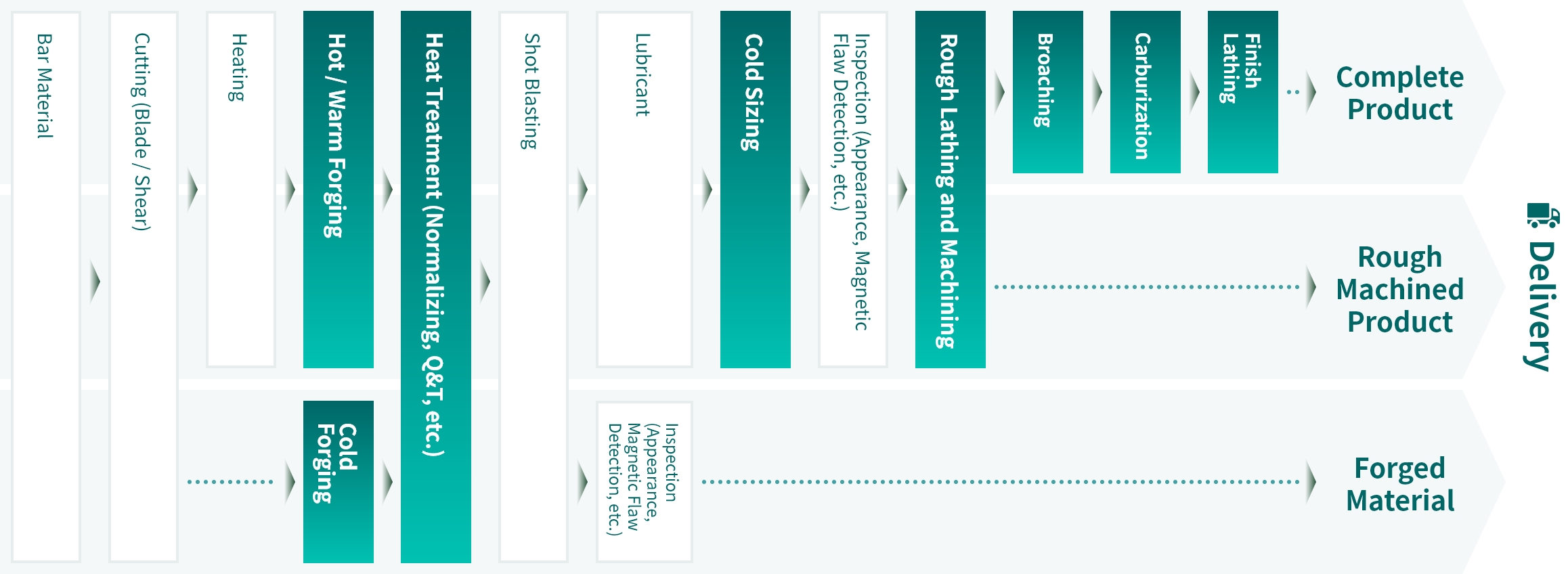

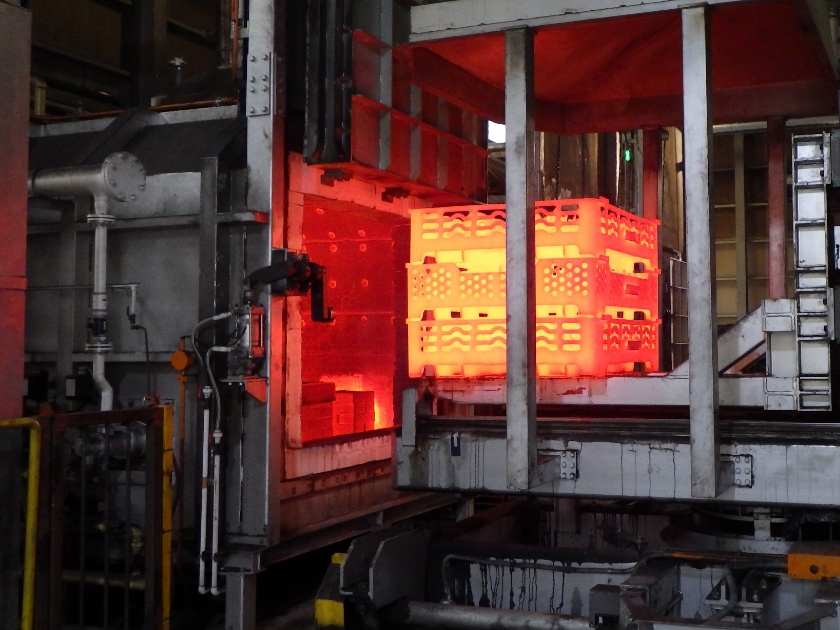

PLASTIC FORMING

HOT FORGING/

WARM FORGING

Various Complicated Shape

Various Complicated Shape

Minimized Yield

Minimized Yield

High-speed Production

High-speed Production

No Dent

No Dent

APPLICABLE GOHSYU SITES

Related Products

- Helical Forged Tooth Gear

- VGR Steering rack bar

- Reduction, Carrier Planetary

- Rear Axle Shaft etc.

COLD FORGING

High Precision

High Precision

High Strength

High Strength

Less Machining

Less Machining

APPLICABLE GOHSYU SITES

Related Products

- Retainer Valve Spring

HOT + COLD FORGING

Cost Reduction

Cost Reduction

High Precision

High Precision

Automated Line

Automated Line

Optimized Shape

Optimized Shape

APPLICABLE GOHSYU SITES

Related Products

- Inner Splined Shaft

- Sleeve Gear

- Parking Gear

- Bevel Gear etc.

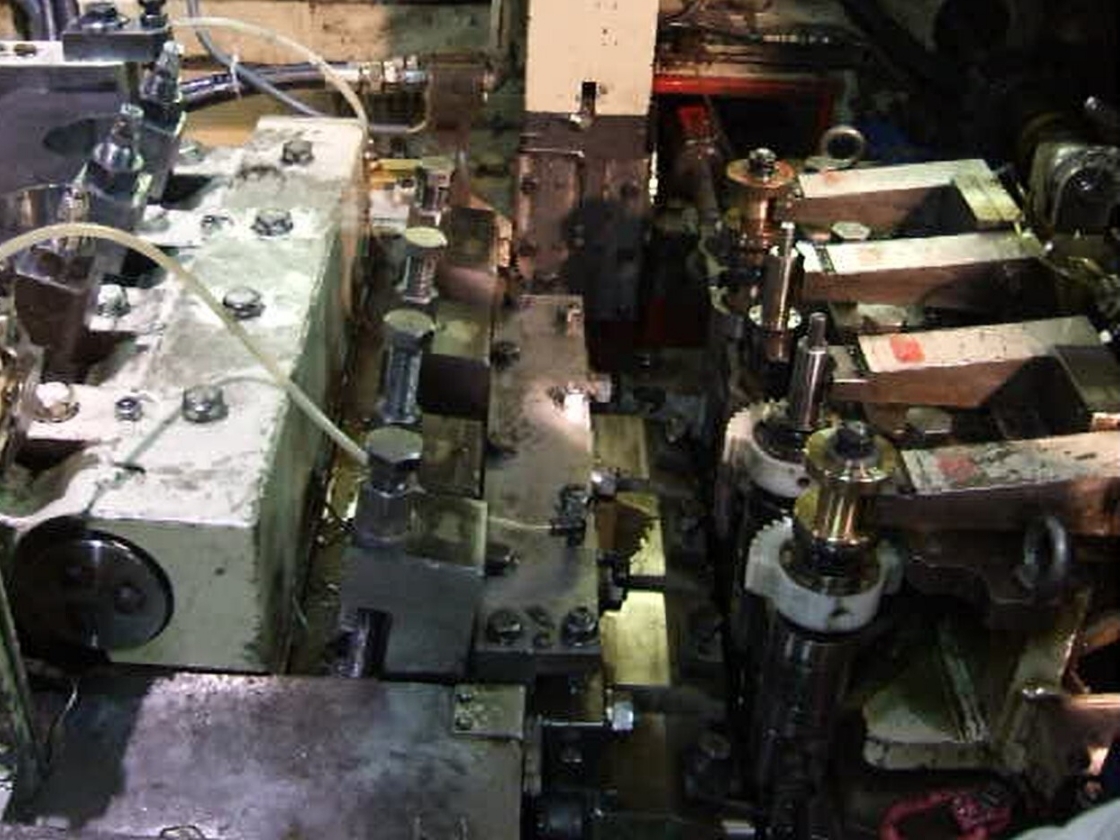

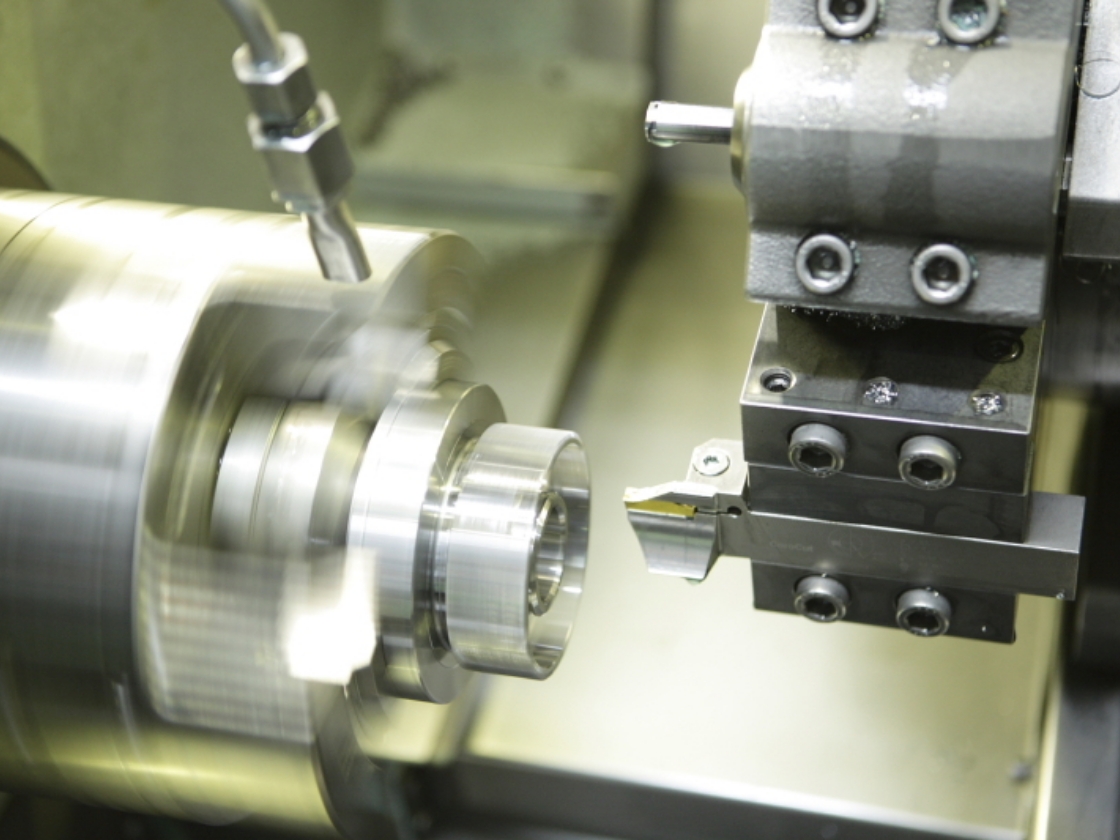

MACHINING

- LATHING

- MACHINING

- LATHE MILL COMBO MACHINING

- BROACHING

HEAT TREATMENT

- QUENCHING and TEMPERING (Q&T)

- NORMALIZING

- NORMALIZING and ANNEALING

- FIA(Forged Isothermal Annealing)

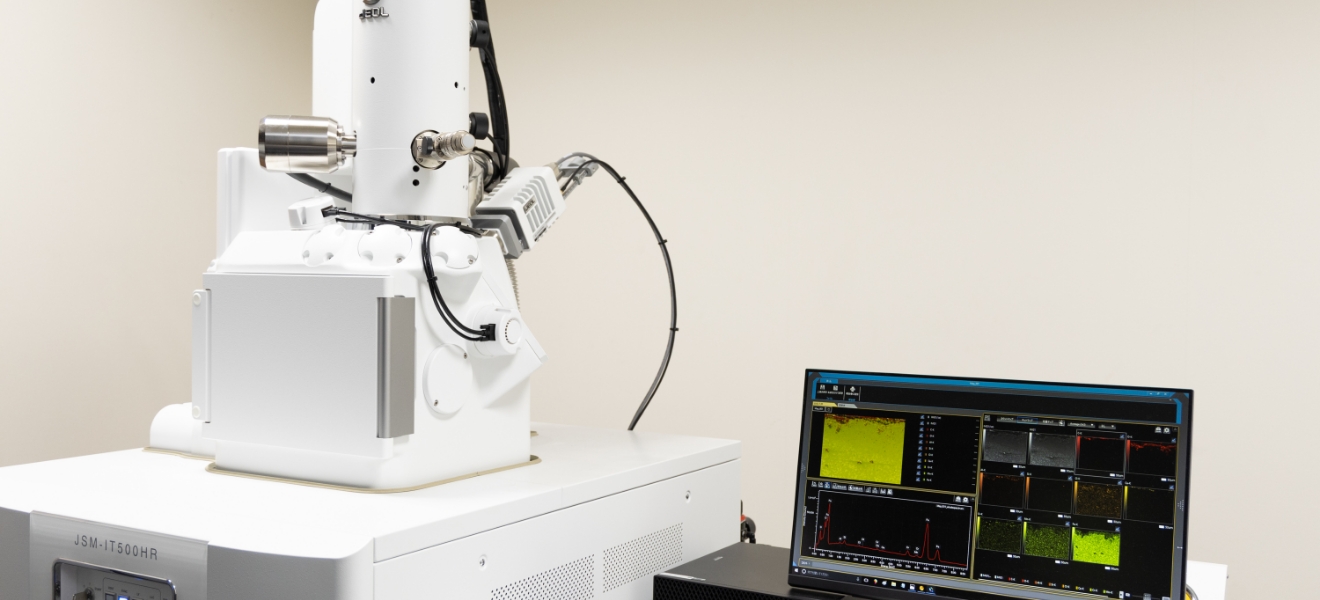

R&D

GOHSYU is continuously working

on R&D from various point of view.

To reach the higher in technology, to meet the needs,

we keep on challenging based on

and exceeding the current method.

MATERIAL

MATERIAL

THE BEST COMBINATION OF

MATERIAL AND HEAT

TREATMENT

PATENT

PATENT

23 PATENTS WITH GOHSYU

ORIGINAL TECHNOLOGY

QUICK

QUICK

SWIFT SAMPLE PROCESS WITH

IN-HOUSE DIE AND ORIGINAL EQUIPMENT.

EXPERIENCE

EXPERIENCE

AUTOMOTIVE PARTS

TECHNOLOGY APPLIED TO

VARIOUS AREA

GLOBAL

GLOBAL

DEVELOPED TECHNOLOGY

IMMEDIATELY REFLECTED

GLOBALLY

Recent R&D

from GOHSYU (YouTube)

WHY GOHSYU?

FORGING EXPERT WITH

TECHNOLOGY AND

EXPERIENCE

01

GOHSYU SUGGESTION IS

PARTICULARLY FOR YOU.

ORIGINAL PARTS FOR

EACH CUSTOMER.

02

ADVANCING, DEEPENING,

AND UPDATING.

CONTINUOUS

“シンカ(Shin-ka)” *

SINCE 1946, AND

FOR THE FUTURE.

03

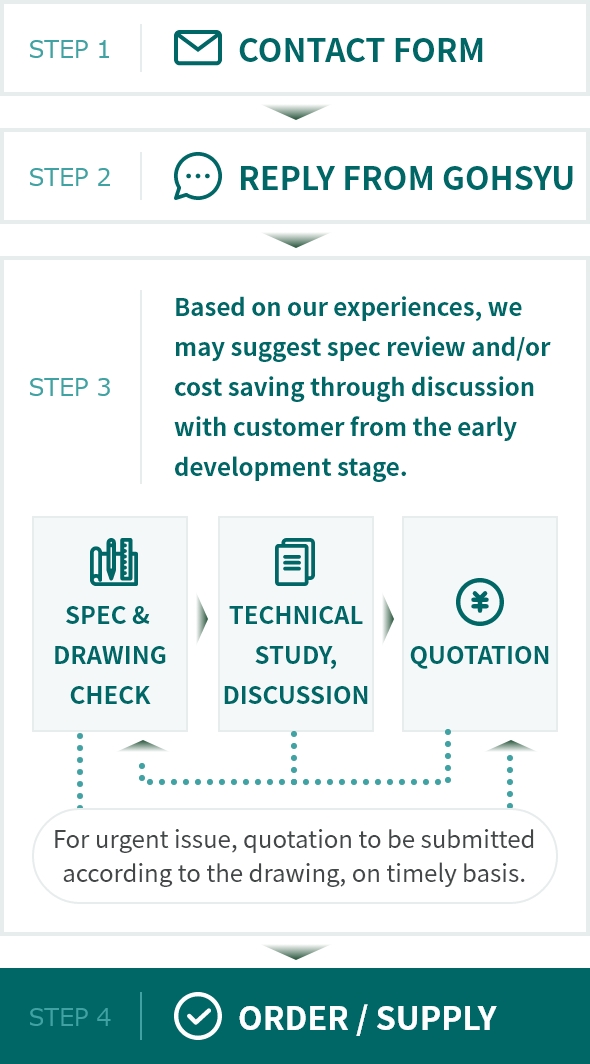

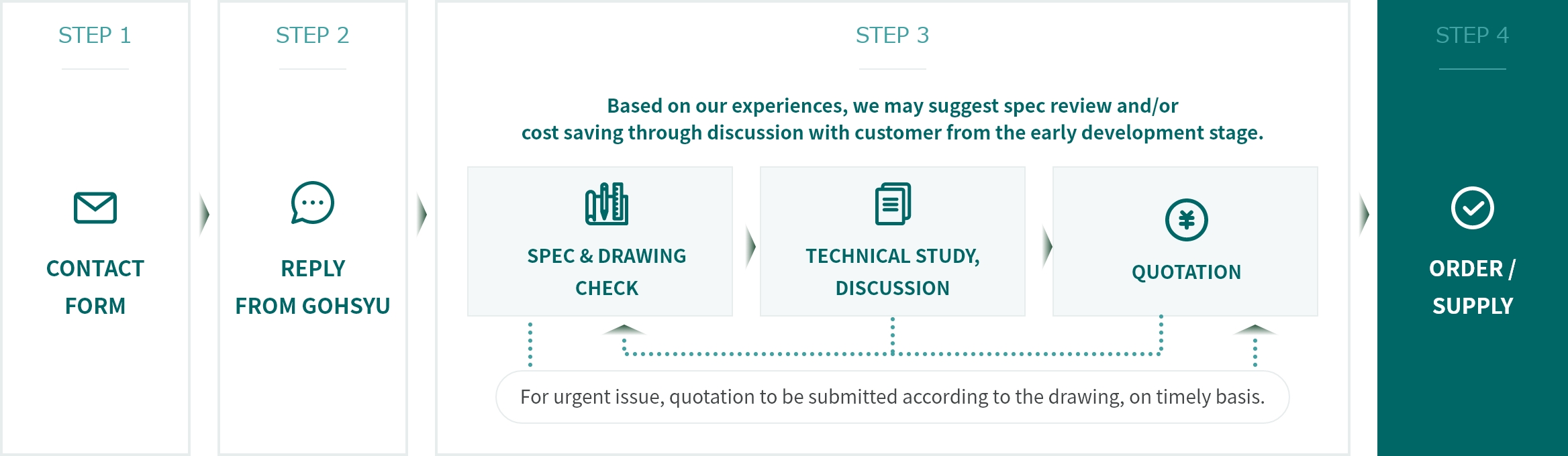

from INQUIRY to SUPPLY

contact