FORMING EQUIPMENT

The core equipment of GOHSYU forging, for high quality mass-production.

HOT FORGING FORMING LINE

2000~

4000TON ×7

×7

4000TON

2000TON

×8

×8

600~

1000TON ×7

×7

1000TON

MONTHLY PRODUCTION

5M PCS

COLD FORGING FORMING LINE

340TON

FORMER

×1

×1

FLOW

FORMING

×3

×3

MONTHLY PRODUCTION

3.1M PCS

COLD SIZING LINE

630~

1600TON ×7

×7

1600TON

200~

600TON ×10

×10

600TON

MONTHLY PRODUCTION

3.1M PCS

HEAT TREATMENT EQUIPMENT

100% GOHSYU In-house, to ensure mechanical property,

machining workability, and to supply with quality assurance.

MATERIAL HEAT TREATMENT

- Continuous quenching and tempering furnace

- Continuous normalizing furnace

- Processing heat treatment furnace

MONTHLY PRODUCTION

2,900TON

SURFACE HEAT TREATMENT

- Carburizing quenching and tempering furnace

MONTHLY PRODUCTION

27TON

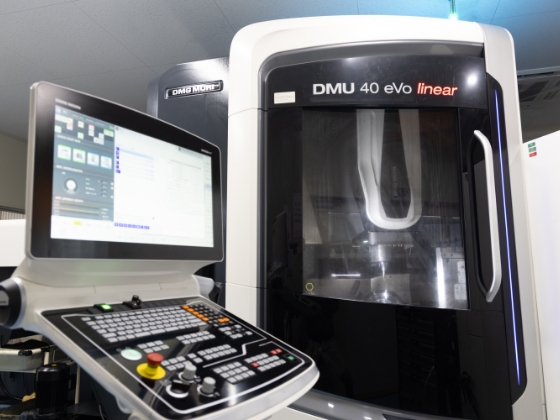

DIE PRODUCTION EQUIPMENT

GOHSYU die is made in-house, thus our own know-how is immediately reflected

in 3D shape to improve precision and to save cost.

- Direct machining tool8

- Die-sinking electrical discharge machine13

- Wire-cut electrical discharge machine4

- Laser processing machine1

- Non-contact 3D measuring1

- 3D CAD/CAM5

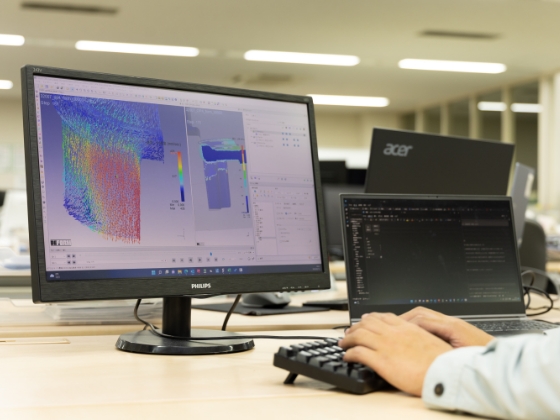

TECHNICAL DESINING EQUIPMENT

With unified system from 2D to 3D and CAE system for preliminary verification,

GOHSYU designing is developed in high accuracy operation.

- 2D CAD Auto CAD

- 3D CAD Unigraphics

- CAE DEFORM-2D

- CAE DEFORM-3D

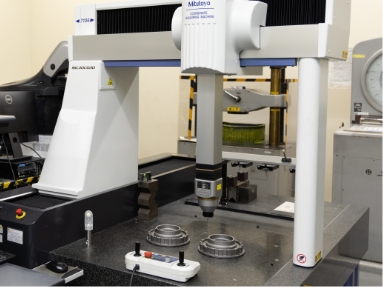

INSPECTION AND TESTING EQUIPMENT

GOHSYU have a system to evaluate the required product function and quality swift and precise

-

3D Scanner

3D Scanner

-

Coordinate Measuring Machine

Coordinate Measuring Machine

- Scanning Electron Microscope (SEM)

- Surftest (surface roughness measuring system)

- Roundness measuring system

- Shape projector

- Engagement tester for bevel gears

- Tension testing machine

- Charpy impact testing machine

- Vickers hardness tester

- Rockwell hardness tester

- Microscope

PRODUCTION and QUALITY MANAGEMENT

Detect and eliminate every single loss. This is one of the important key to manage high productivity.

We must see the actual place in the factory, must foresee the needs, and must take action on time.

GOHSYU has established the control system based on ISO with

our experience and accumulated data analysis and evaluation.

Our manufacturing and quality are controlled by unified system of human and IT.

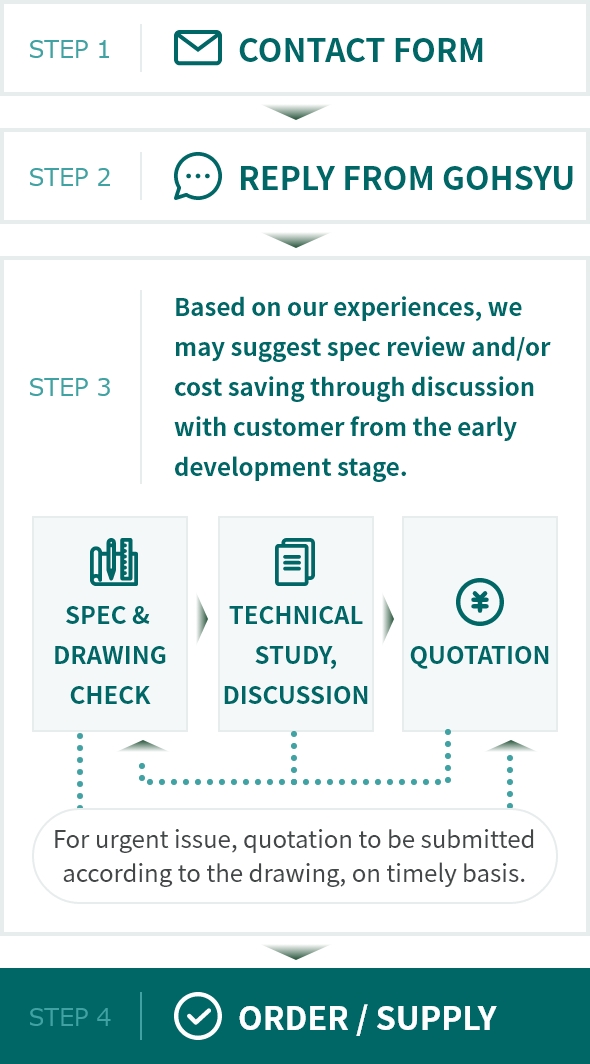

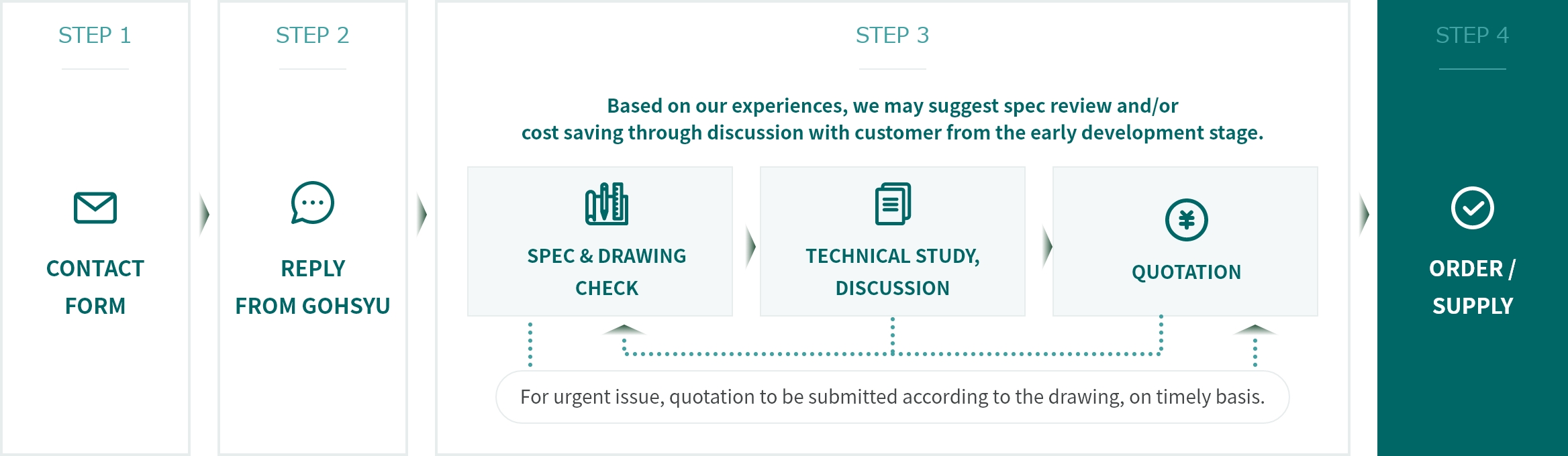

from INQUIRY to SUPPLY

contact