WHAT IS “FORGING”?

forge [fôrj] たん‐ぞう【鍛造】

What is the difference from other methods?

Process

Methods

Methods

FORGING

MACHINING

CASTING

FIBER

FLOW

FLOW

ADVANTAGES OF FORGED PRODUCT

strong

strong

STRONGER, and STABLE

MECHANICAL PROPERTY

green

green

SAVING MATERIAL by FORMING

NEAR NET SHAPE

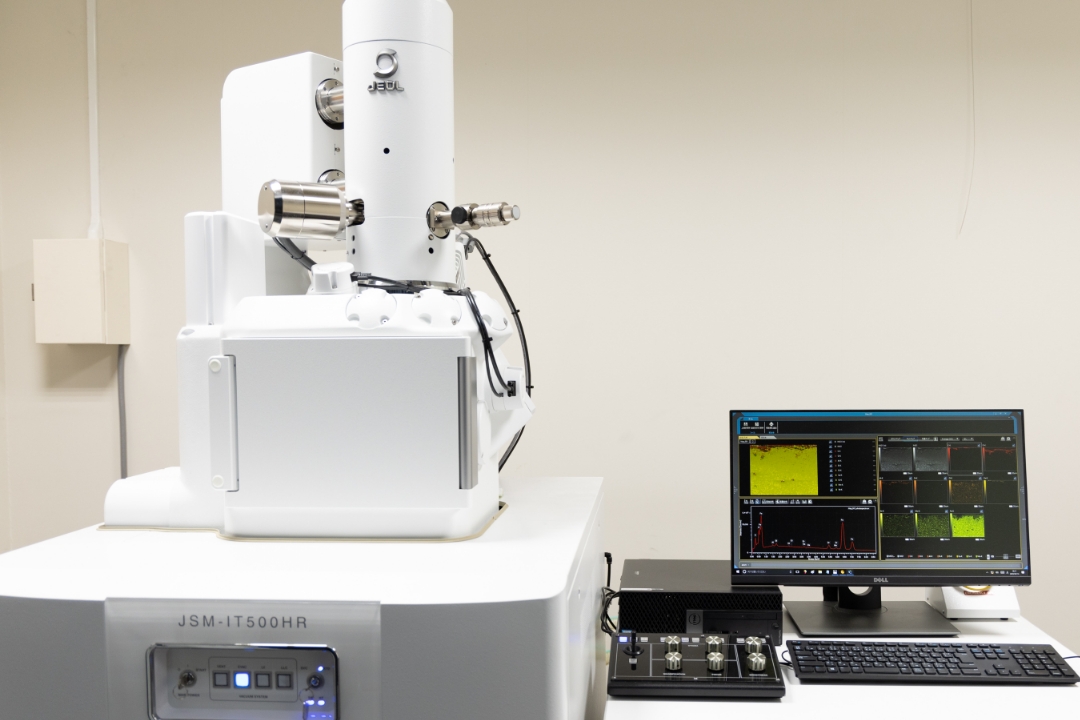

GOHSYU’S FORGING TECHNOLOGY

SINCE 1946

CONTINUOUS EVOLUTION BEGAN…

WE HAVE CONFIDENCE

IN

OUR TECHNOLOGY

AND EQUIPMENT

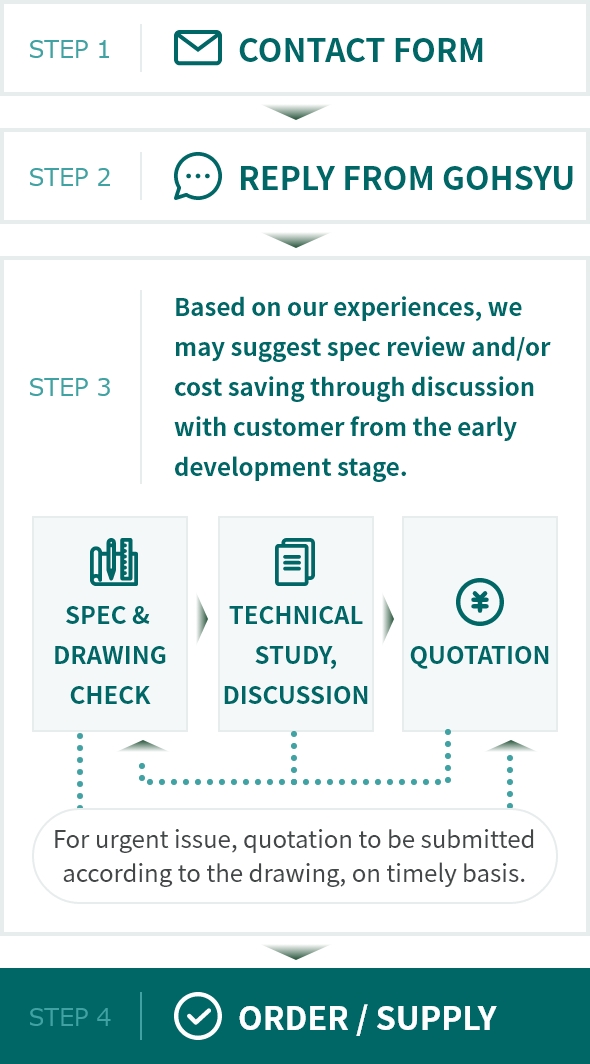

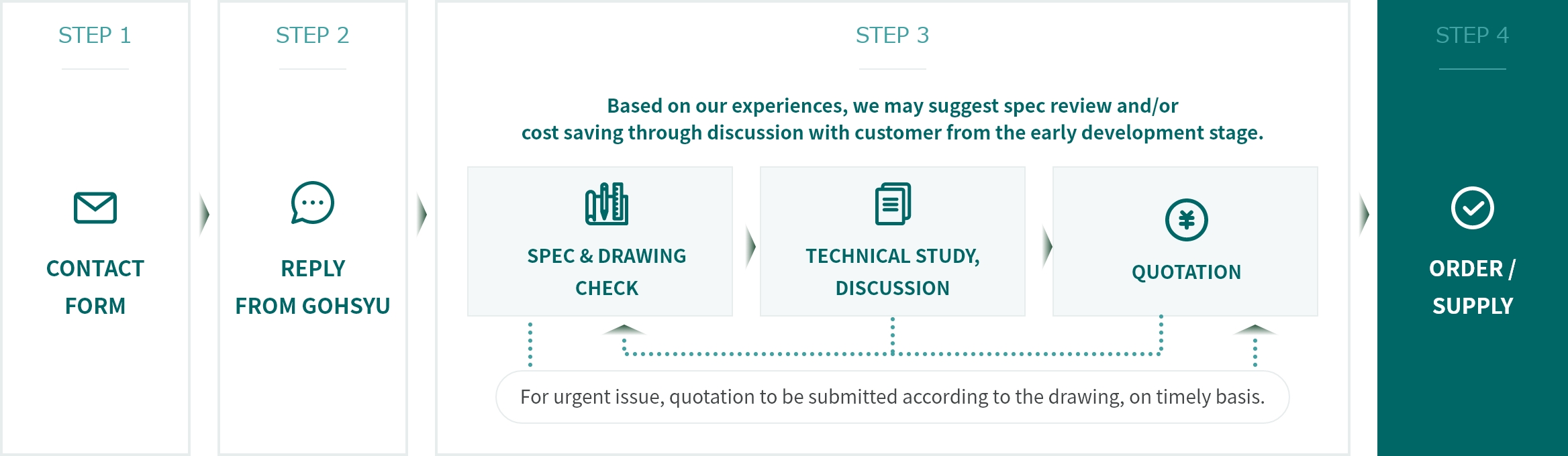

from INQUIRY to SUPPLY

contact