PRODUCTS

(BY INDUSTRY)

AUTOMOBILE EV-UNIT

Helical Tooth Forged Gear

| Forging Method |

|

|---|---|

| Material | SCR, SCM, and other required material can be applied. |

| Part Name | Final Gear (Reduction unit) |

| Spec |

|

|---|

Deep Hollow Long Shaft

| Forging Method |

|

|---|---|

| Material | SCR, SC |

| Part Name | Motor Shaft |

| Spec |

|

|---|

Inner Splined Shaft

| Forging Method |

|

|---|---|

| Material | SCR, SC, and others |

| Part Name | Output Shaft |

| Spec |

|

|---|

Flanged Shaft

| Forging Method |

|

|---|---|

| Material | SCR, SC, and others |

| Part Name | Shaft with Gear |

| Spec |

|

|---|

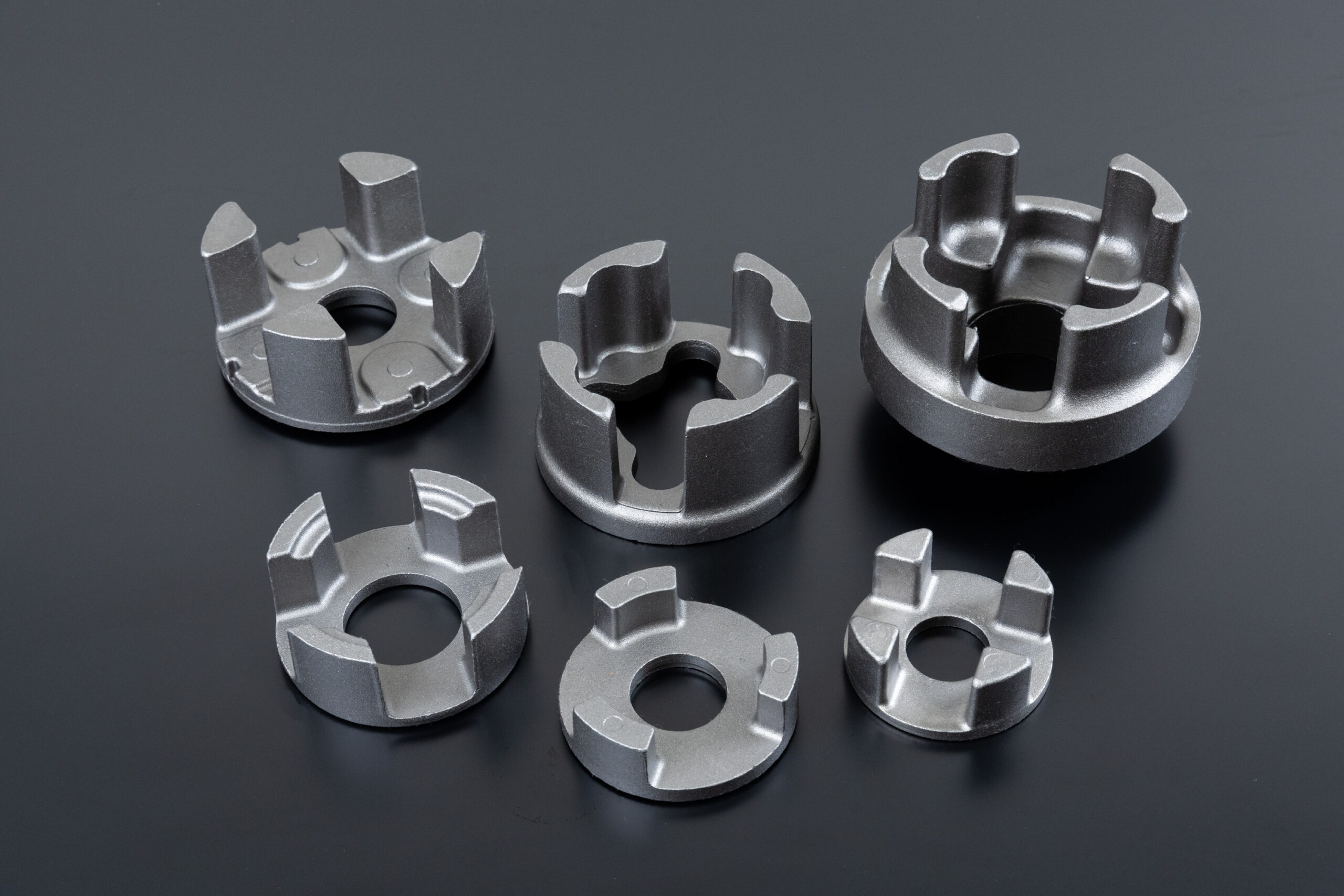

Case with Boss Shape

| Forging Method |

|

|---|---|

| Material | SCR, SC, and others |

| Part Name | Carrier, Planetary (Planetary Reduction Units) |

| Spec |

|

|---|

AUTOMOBILE TRANSMISSION

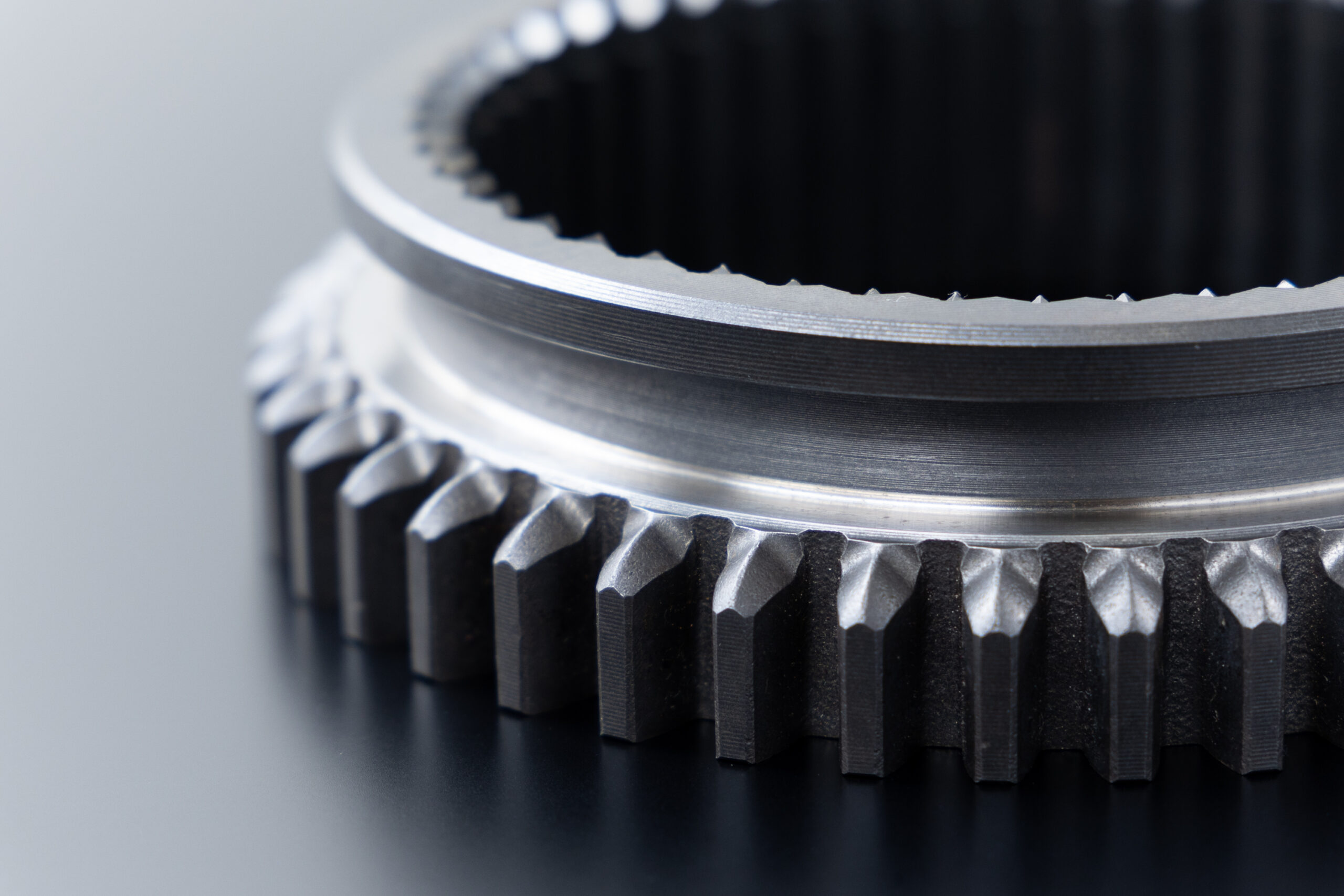

Round Chamfered Gear

| Forging Method |

|

|---|---|

| Material | SCR, SCM, and others |

| Part Name | Sleeve Gear |

| Spec |

|

|---|

Thin Gear

| Forging Method |

|

|---|---|

| Material | SCR, SCM, and others |

| Part Name | Manual Clutch Gear (Automobile) |

| Spec |

|

|---|

Parking Gear

| Forging Method |

|

|---|---|

| Material | SCR, SCM |

| Part Name | Parking gear |

| Spec |

|

|---|

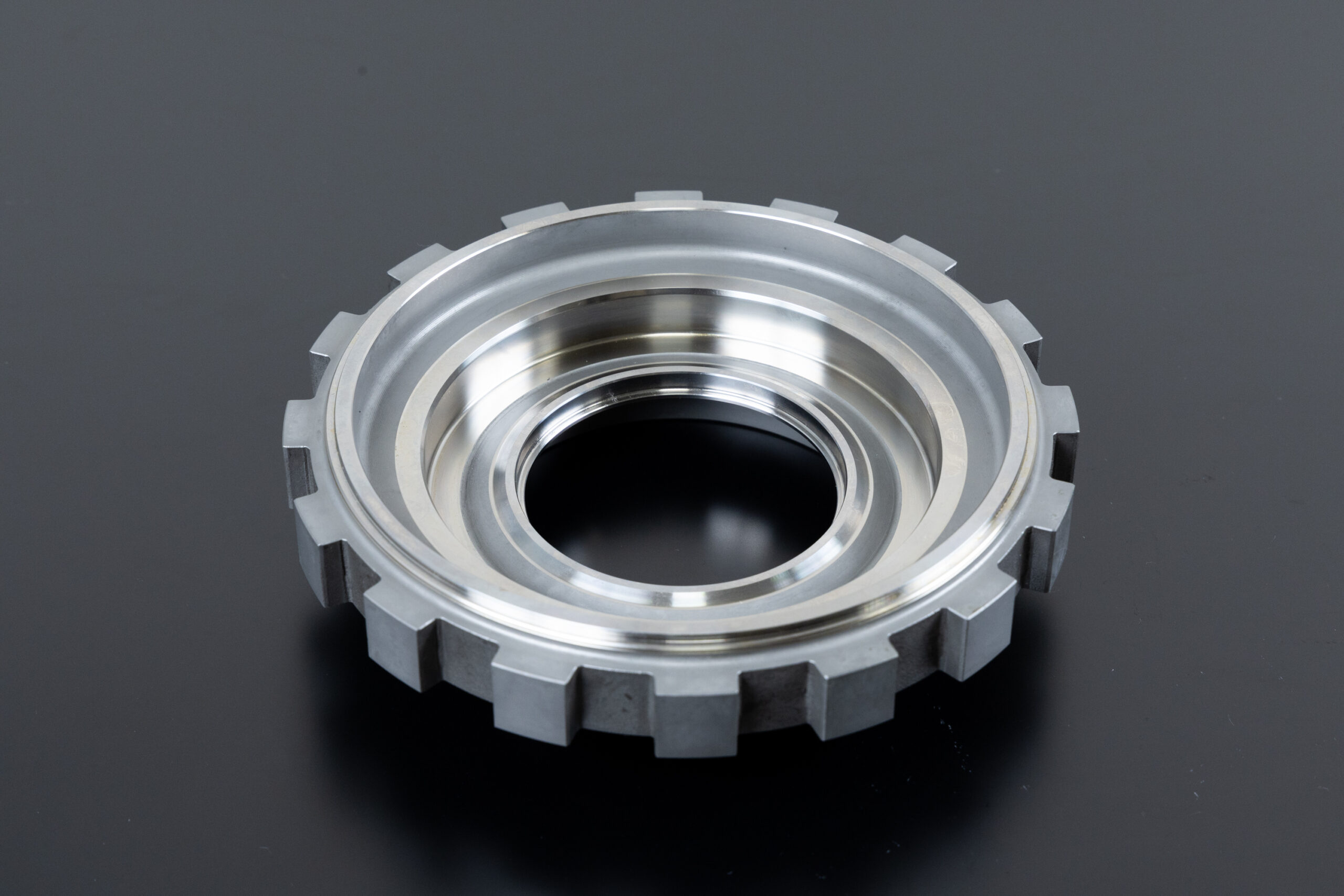

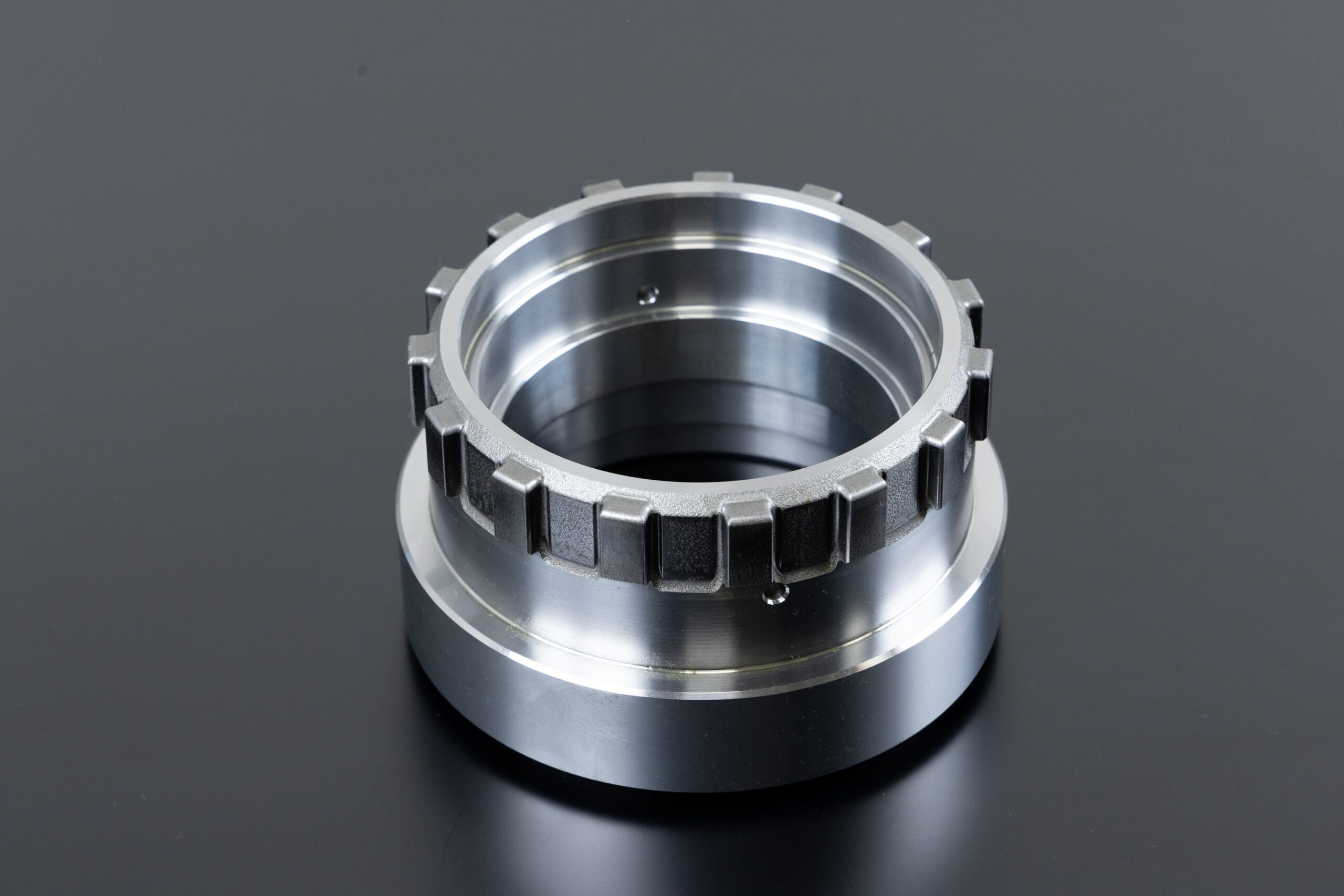

Cylinder Sheave

| Forging Method |

|

|---|---|

| Material | SC |

| Part Name | Cylinder Sheave |

| Spec |

|

|---|

AUTOMOBILE CHASSIS

Randum Pitch Tooth

| Forging Method |

|

|---|---|

| Material | SC, SC-V |

| Part Name | VGR (Variable Gear Ratio) Steering Rack Bar |

| Spec |

|

|---|

Axle Shaft

| Forging Method |

|

|---|---|

| Material | SC |

| Part Name | Axle Shaft (Automobile) |

| Spec |

|

|---|

Hub

| Forging Method |

|

|---|---|

| Material | SCR, SC, SC-V, and others |

| Part Name | Hub |

| Spec |

|

|---|

Triple Clamp

| Forging Method |

|

|---|

| Spec |

|

|---|

Boss Part

| Forging Method |

|

|---|---|

| Material | SC, SC-V |

| Part Name | Joint Yoke (Automobile) Joint Flange (Automobile) |

| Spec |

|

|---|

Large Randum Boss Part

| Forging Method |

|

|---|---|

| Material | SC-V |

| Part Name | Steering Knuckle (Automobile) |

| Spec |

|

|---|

AUTOMOBILE ENGINE

Small Round Parts (Retainer)

| Forging Method |

|

|---|---|

| Material | SCR, SCM |

| Part Name | Valve Spring Retainer (Automobile, Motorcycle, Agriculture) |

| Spec |

|

|---|

Connecting Rod

| Forging Method |

|

|---|---|

| Material | SC, SC-V, and others |

| Part Name | Connecting Rod / Con Rod (Automobile, Motorcycle, Agriculture) |

| Spec |

|

|---|

Crankshaft

| Forging Method |

|

|---|---|

| Material | SC, SC-V, SCM, and others |

| Part Name | Crankshaft (Motorcycle, Agriculture, Robots) |

| Spec |

|

|---|

Delivery Pipe / Common Rail

| Forging Method |

|

|---|---|

| Material | SC, SC-V, SCM |

| Part Name | Common Rail |

| Spec |

|

|---|

SUS (Stainless) Part

| Forging Method |

|

|---|---|

| Material | SUS |

| Part Name | Engine related parts (Automobile) |

| Spec |

|

|---|

AGRICULTURE

Small Round Parts (Retainer)

| Forging Method |

|

|---|---|

| Material | SCR, SCM |

| Part Name | Valve Spring Retainer (Automobile, Motorcycle, Agriculture) |

| Spec |

|

|---|

Connecting Rod

| Forging Method |

|

|---|---|

| Material | SC, SC-V, and others |

| Part Name | Connecting Rod / Con Rod (Automobile, Motorcycle, Agriculture) |

| Spec |

|

|---|

Crankshaft

| Forging Method |

|

|---|---|

| Material | SC, SC-V, SCM, and others |

| Part Name | Crankshaft (Motorcycle, Agriculture, Robots) |

| Spec |

|

|---|

INDUSTRIAL ROBOT

Crankshaft

| Forging Method |

|

|---|---|

| Material | SC, SC-V, SCM, and others |

| Part Name | Crankshaft (Motorcycle, Agriculture, Robots) |

| Spec |

|

|---|

INFRASTRUCTURE

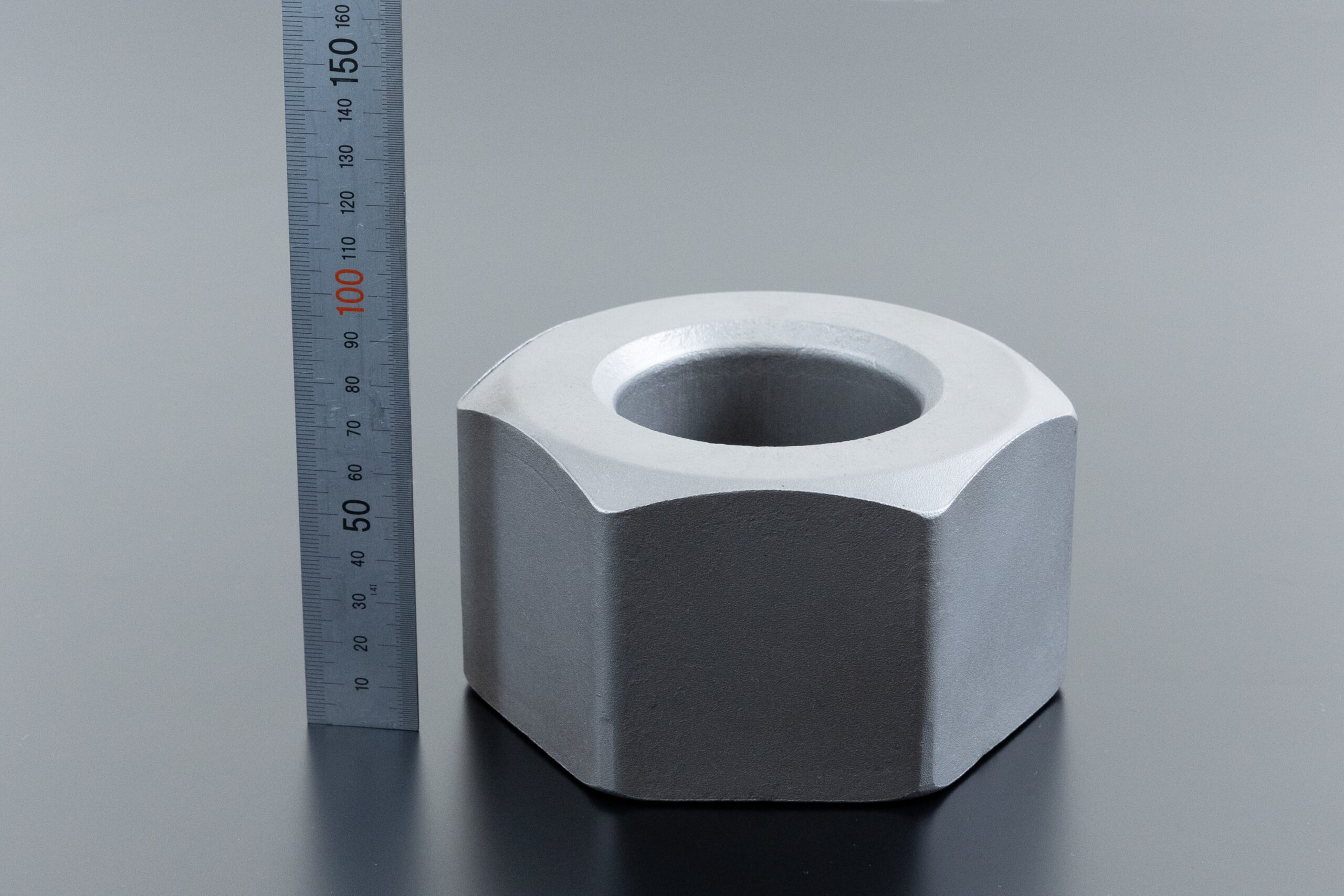

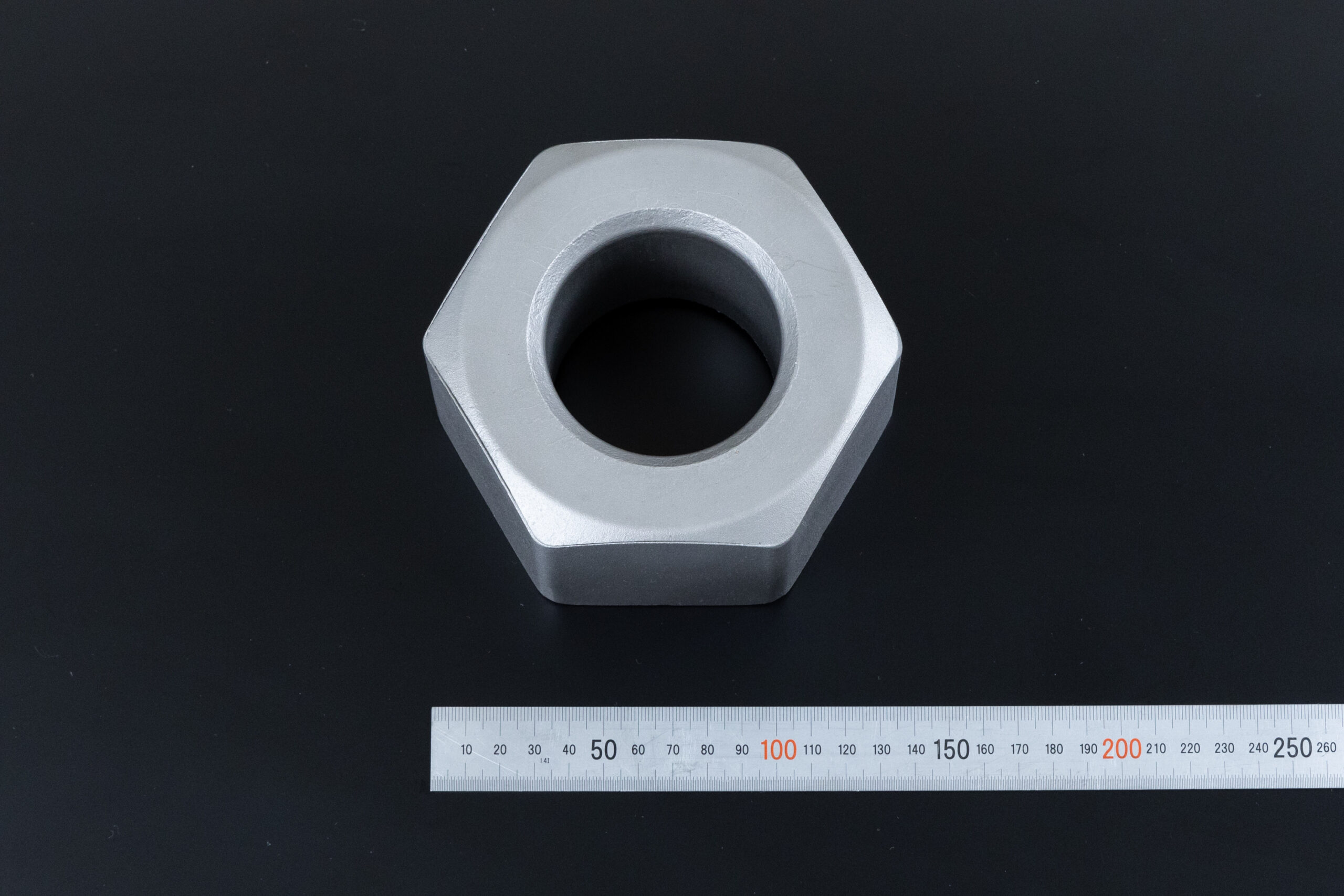

Nut (Large Size)

| Forging Method |

|

|---|---|

| Material | SCM |

| Part Name | Nut (Large Size) |

| Spec |

|

|---|

MEDICAL

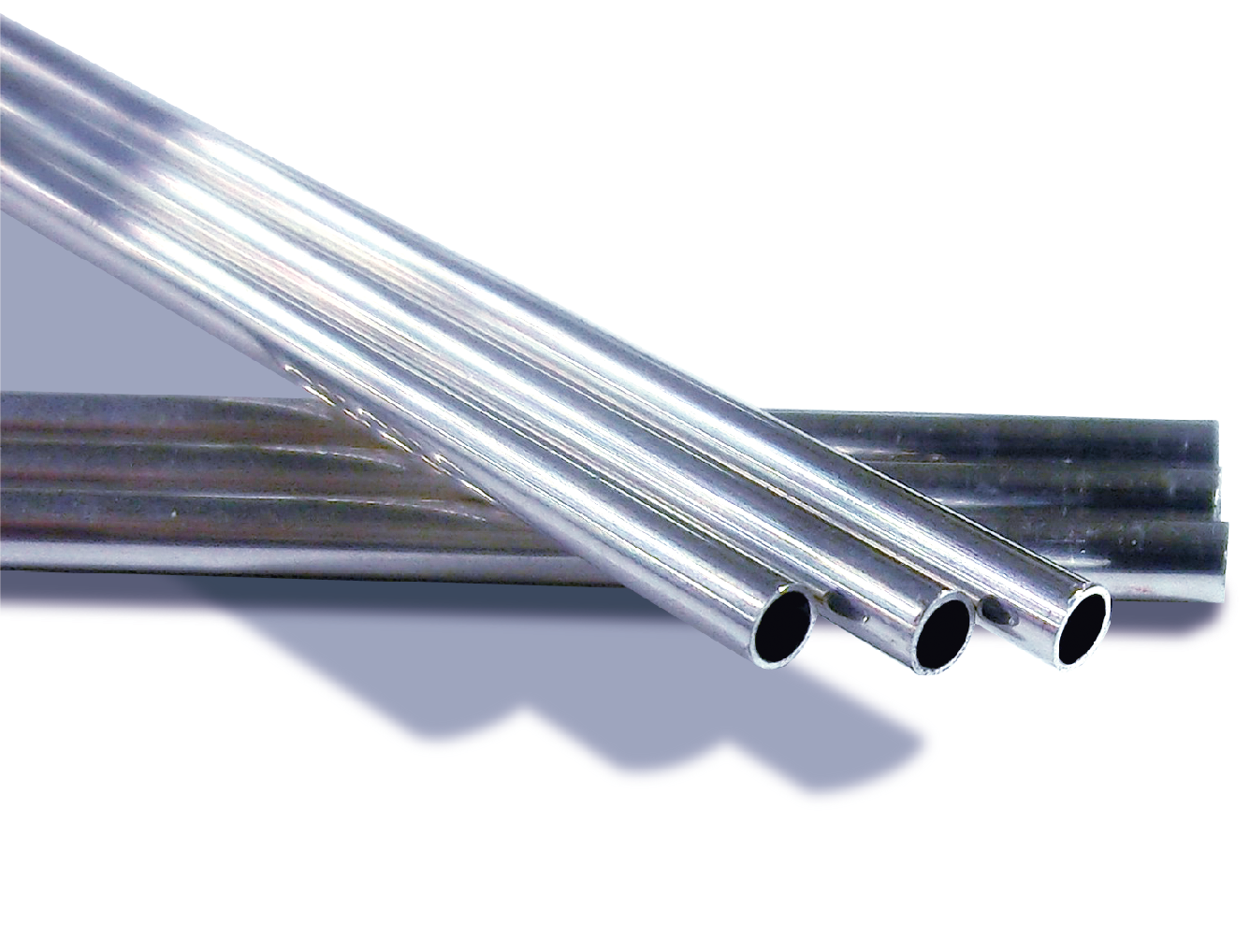

Magnesium Pipe

| Forging Method |

|

|---|---|

| Material | Mg |

| Part Name | Mg pipe (Medical) |

| Spec |

|

|---|

NEW ITEM INQUIRIES ALSO WELCOME!

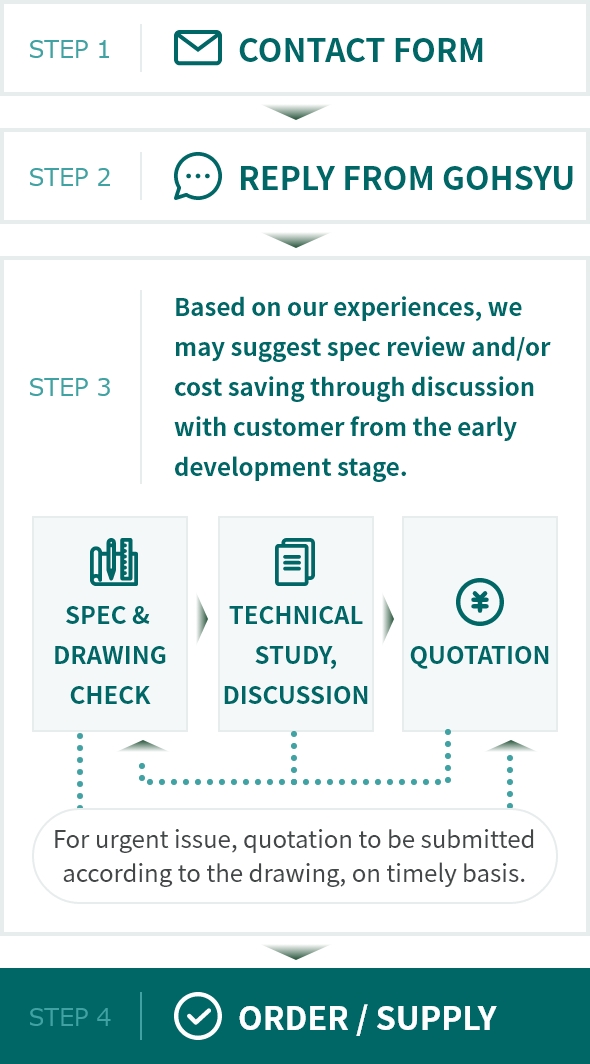

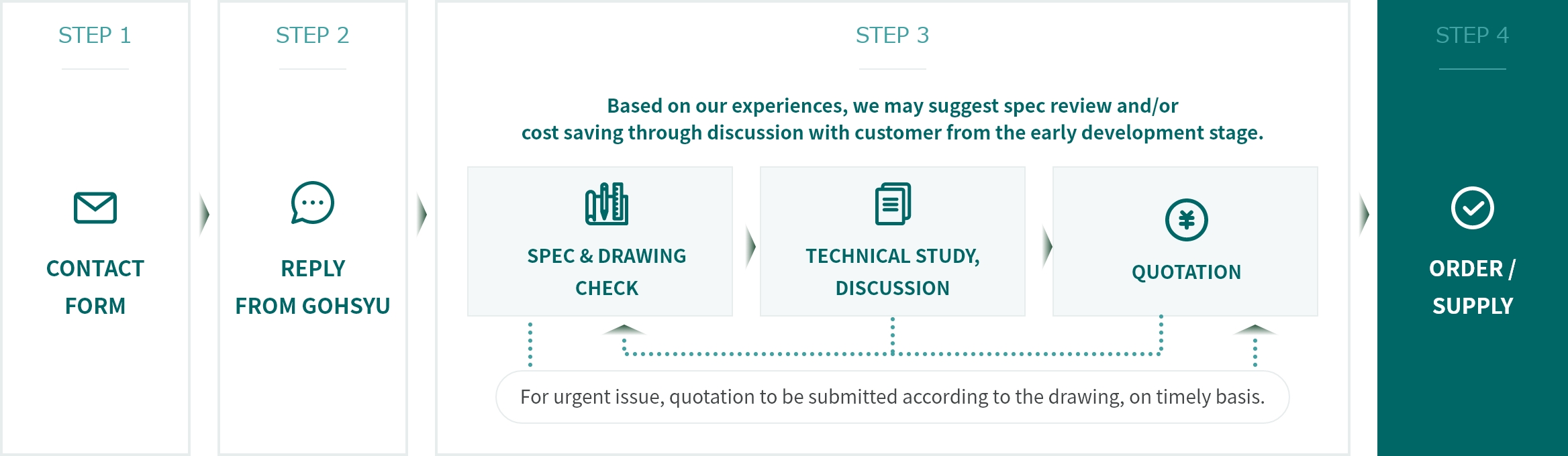

from INQUIRY to SUPPLY

contact